It scarcely seems possible that BMW Motorrad’s lineup-leading S1000RR sportbike actually made its official public debut a whole decade and a half ago in April 2008, with deliveries beginning the following year. Even though 15 years is a long time, especially in the Superbike arena, where serious players like BeeEm, as well as Ducati, Aprilia, and the Japanese, don’t stint on investing in fast-moving high-end technical R&D in pursuit of engineering excellence, the German brand’s first-ever customer motorcycle with a transverse-mounted four-cylinder has maintained its leading edge reputation for both mechanical and electronic innovation ever since then, and the newly introduced latest version is no exception.

This is because, for the coming 2023 model year, BMW has essentially uprated its existing volume production version of the bike by transplanting a good chunk of the array of technical upgrades available until now only to around 1,200 well-heeled or well-sponsored users of the M1000RR, the uber-expensive, uber-performing version of BMW’s street-legal superbike that’s been on sale for the past two years, essentially as a homologation special for Superbike racing. As such, it earned its keep by powering Peter Hickman to a trio of record-breaking race wins at the 2022 Isle of Man TT – albeit without breaking his astounding outright single-lap record of 135.452mph set in the 2018 Senior TT on an S1000RR – while also registering hard-fought race wins for Hicky and Danny Buchan in the hot-as-Hades BSB series. However, thus far the BMW has failed to be a true contender for top honors in World Superbike for the past decade, ever since Marco Melandri finished third in the points table on an S1000RR in 2012 – and that’s despite proven WSBK winner Scott Redding joining the factory team last season.

An all-new engine

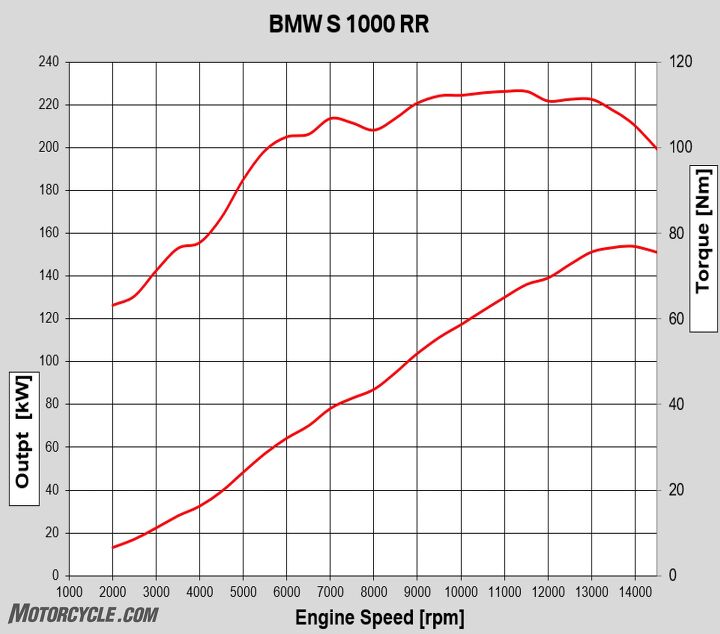

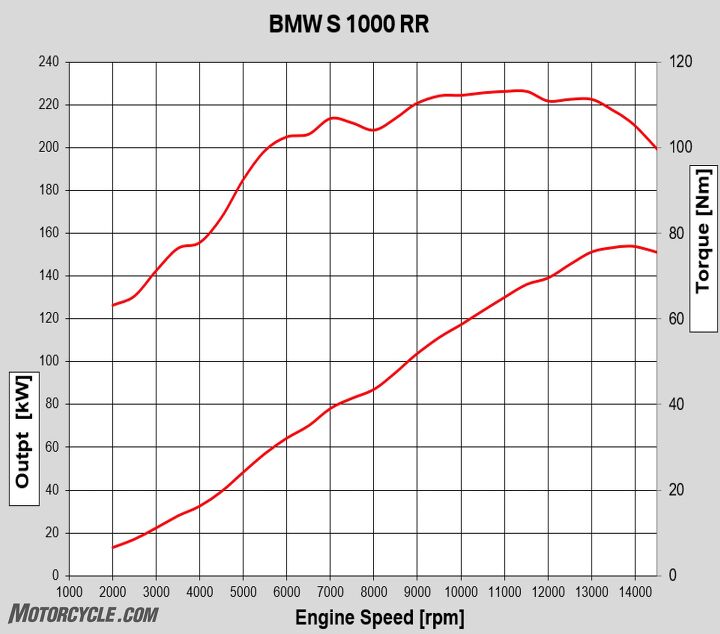

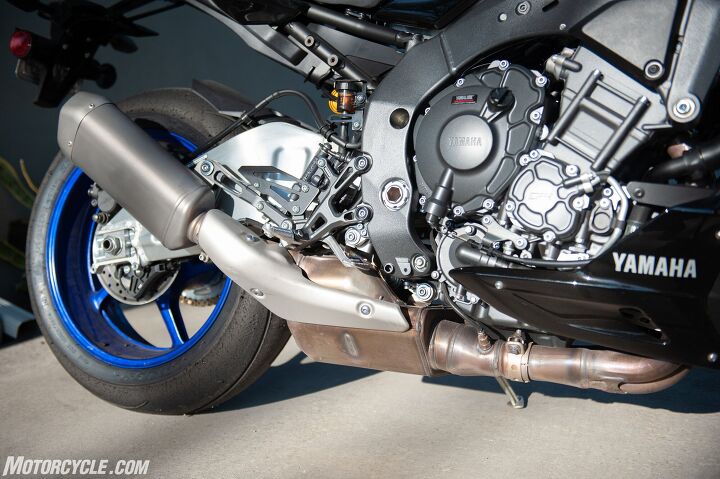

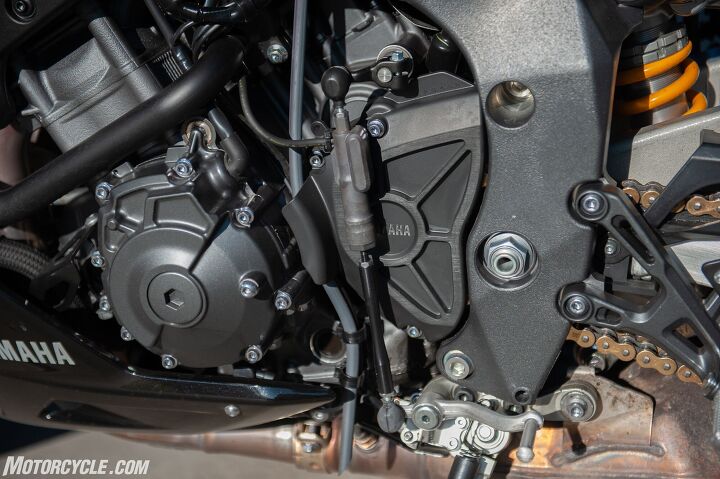

While BMW’s original game-changing, ultra short-stroke 2009 S1000RR set new standards on debut for series production four-cylinder Superbike technology, in 2019 there was a heavy revamp with less than 5% of the 8,200 components making up the entire motorcycle, including the engine, carried over from before. BMW Motorrad management was looking to significantly improve on the existing bike’s performance, meaning they wanted it to be one second faster on the racetrack, more than 10kg lighter, and easier to control, with improved rideability. Doing this entailed developing an all-new, lighter, more compact and more powerful 999cc engine measuring an unchanged 80 x 49.7 mm, which while 12mm narrower than its predecessor, also weighed 8.8 lbs less. This was thanks partly to a crankshaft 4 lbs lighter than before carrying 4mm shorter and 10% lighter conrods, which together delivered even better pickup throughout the rev range. But the most significant step that’s been carried forward alongside these other features to the 2023 model was the application of BMW’s patented ShiftCam Technology introduced on that year’s R1250GS adventure tourer’s Boxer motor, then transferred to BMW’s four-cylinder range. This combines both variable intake valve timing and differential valve lift, all in the same package, and together with revised cam profiles is responsible for at least 73.8 lb-ft of torque being available between 5,500 rpm and 14,600 rpm, where the short-stroke engine’s unchanged soft-action limiter cuts in. And that 8.8-lb weight saving came despite the 2.2-lb weight penalty entailed in fitting the ShiftCam system.

BMW S1000RR Engine’s Shiftcam Technology Explained

BMW Motorrad’s ShiftCam Technology owes nothing to the Vanos variable valve timing technology developed 30 years ago for use on BMW cars, nor the Valvetronic variable valve lift system introduced in 2001, both of which were considered too bulky for motorcycle use. Instead, the radical, highly innovative ShiftCam system in the S1000RR engine’s cylinder heads combines both variable valve timing and differential valve lift, all in the same package, as a means of optimizing cam timing and duration for what you’re asking the engine to do. For part-throttle openings, or lower down in the rev range, the cam has a shorter lift and reduced duration, meaning the inlet valves are open less. But ask for more throttle or higher revs and the cam shifts sideways, bringing into play a higher lift, longer duration cam lobe, more suited to outright performance.

.

This is achieved by having the inlet camshaft of each cylinder incorporating two different cam profiles mounted side by side on the same shaft. One of these is a partial-load cam, which has been configured to deliver improved fuel consumption and refinement at part-throttle. The other is a full-load cam designed for enhanced output via more aggressive throttle openings, which delivers longer duration inlet valve openings. By means of an axial shift from side to side of each inlet camshaft, the paired inlet valves on each cylinder are activated via their finger followers by either the partial-load or the full-load cam, depending on engine rpm, gear selected, and throttle load, with that axial shift affected by means of a pin that’s electronically actuated via the ECU, operating the shift gate on the camshaft.

.

This means that as the throttle opens wider via the twistgrip, the electronic actuator lifts a pin to lock into the inlet camshaft gate. The rotation of the camshaft then permits the pin to draw the camshaft sideways, to bring the more aggressive longer duration cam lobes into line with the valves. When the throttle is closed, the camshaft is pulled back across the cylinder head, and onto the less aggressive smaller profile cam employed for normal use. Either way, the change is practically instantaneous, taking just 10 milliseconds to accomplish. That’s less than the blink of an eye.

.

Additionally, the variable configuration of the cam geometry also enables a variation in the inlet valves’ stroke. While the full-load cam provides maximum valve stroke, the partial-load cam delivers reduced stroke. There is also a phased differential opening between the left and right-hand inlet valves in each cylinder, in terms of both stroke and angular position. This phased shift means that the two inlet valves are opened a differential amount in terms of lift – i.e. one more than the other – and on a time-staggered basis. This helps create additional swirl for the incoming charge of air and fuel, and thus greater agitation of the mixture as it flows into the combustion chamber. This results in both improved combustion – so, a bigger bang – as well as more complete burning of the fuel, thus ensuring reduced emissions and a claimed up to 4% lower fuel consumption. And the smoother delivery and broader spread of torque also reduces the propensity of the bike to pull wheelies, as there isn’t such a fierce spike in the torque delivery. But the biggest advantage of the ShiftCam Technology in dynamic terms is the noticeable increase in ridability in both normal road conditions, and in high performance use on the racetrack, thanks to the significantly enhanced midrange power, and the wide spread of torque it delivers.

Now, in pursuit of greater performance at higher revs, BMW has transposed the M1000RR’s airbox and cylinder head to the volume production Euro 5-compliant 2023 S1000RR, though its new intake porting is cast in here rather than milled out, as on the M RR. As before, the uprated S RR engine is fitted with a variable-length intake system whereby the height of the inlet trumpets atop the 48mm throttle bodies that are now shorter overall for 2023, is further reduced via an electric servomotor mounted on the airbox operating at 11,900 rpm (a hefty 2,900 revs higher than before) to enhance top end performance in conjunction with the ShiftCam Technology system. This has allowed BMW to raise power by 3bhp to 207bhp at 13,750 rpm, 250 revs higher than previously, with peak torque unchanged at 83 lb-ft, but delivered 500 rpm higher at 11,000 rpm.